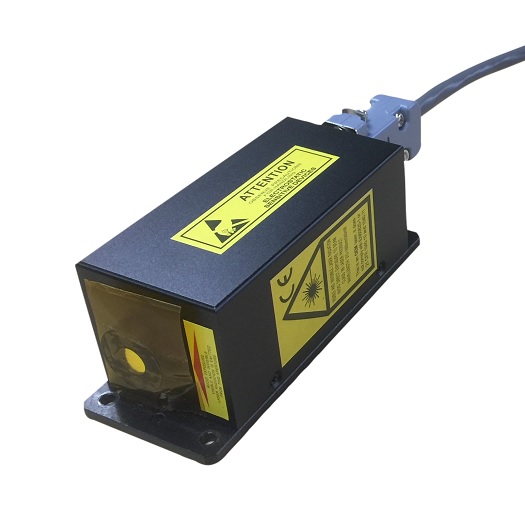

Pavilion Integration WhisperIT® laser modules are used by the world’s leading suppliers of food and recycling sensor-based sorting equipment to provide advanced grading, sorting, and analytical feedback, maximizing throughput while minimizing waste.

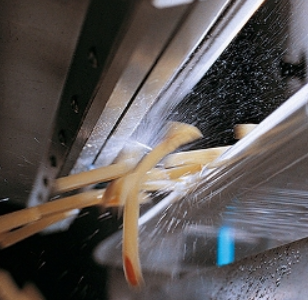

Food growers, packers, and processors around the world use advanced laser-based machines to sort a variety of fresh whole products and processed food to maximize output and minimize waste. Laser machines sort based on color, structure, and biological characteristics. Laser scanning detects contaminants even when the acceptable products and the defects present the same color.

Sensor technology provides the highest efficiency, precision, and speed. Working much faster than traditional sorting technologies and prohibiting even the smallest sized particle from falling through the detection grid. Sensor technologies ensure high-speed processing and provide information on material, shape, size, geometry, color, defect and damage characteristics, and the location of objects.

Lasers are used to detect objects that cannot be seen from NIR-Sensors like black plastics (PP, PE, PET etc.), glass and waste items. Capabilities include:

- Detection of black plastics and glass

- Independent background system leads to stable detection

- Flexible integration to existing products with low maintenance

- Sorting out impurities from paper (e.g. black objects and polymers)

- Peak performance with low energy consumption